"Reliably Accurate"

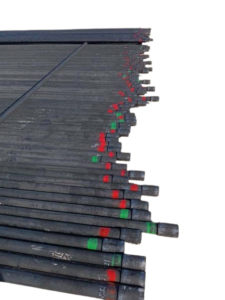

WellHead Tubing EMI Inspection

When accuracy and precision matter, look to Bandit Tech to serve your Wellhead Tubing EMI Inspection needs or Tubing Inspection Trip Tool. We offer state of the art EMI equipment, trained technicians, and reliable service at a reasonable price. Give us a call for your next job.

RELIABLE ACCURACY

Utilizing NON-CONTACT magnetic principles, we scan tubing while ignoring fluids, wax, sand and other impairing debris.

Tubing Sizes We Inspect

2 3/8" 2 7/8" 3 1/2"

FLAW DETECTION

Monitoring both magnetic fields, around and within the tubing, any flaw such as rod-wear or corrosion are detected and analyzed by the electronics located up to 120 feet away. The embedded computer within the electronics sorts out the defects and produces, on a laptop computer, a trace-like record of each tube and a profile of the whole string.

Processing Power

- 2-Flaw Channels

- 1-Split

- 4-Wall Loss

- 1-Total Wall

FAST and PRECISE

A programmable power supply produces a constant current for magnetizing the tubing that can be inspected at a rate of up to 200 ft/min

Example Report

Gives us a call for your next Wellhead Tubing EMI Scan Job

Safety is front of mind at bandit tech

All employees are Safe Land and OSHA 1910 compliant. Additionally, safety compliance is at the core of every task completed at Bandit Tech. Whether we are driving back from a tubing emi scanning job or hardbanding a joint of drill pipe safety is always the number one priority. We are also a proud member of ISN, Veriforce and provide in-house API & TH Hill training. We strongly believe competency is an important part of working safely.